Pattern color is light/saturation is insufficient

Check whether the ink stack has sufficient suction and whether the DTF printhead is tightly sealed. Check whether the nozzle has not been sealed for a long time, causing some nozzles to dry out. Confirm whether the nozzle working voltage and pulse width parameters match the current accessory status.

Uneven ink discharge from the nozzle/printed pattern disconnection

Please check whether the ink sac is aging and hardening, resulting in insufficient ink supply flow rate. Check whether the negative pressure of the ink supply system is stable and whether there is backflow of ink. Check whether there are bubbles or impurities in the ink blocking the pipeline.

Ink flying, drawing or pattern deviation

You can check whether the data line is aging and has poor contact. Check whether the static discharge of the nozzle is normal and whether there is static interference. Check whether the pressure regulation of the ink system is balanced and whether there is overpressure or insufficient suction.

Daily inspection suggestions for key accessories

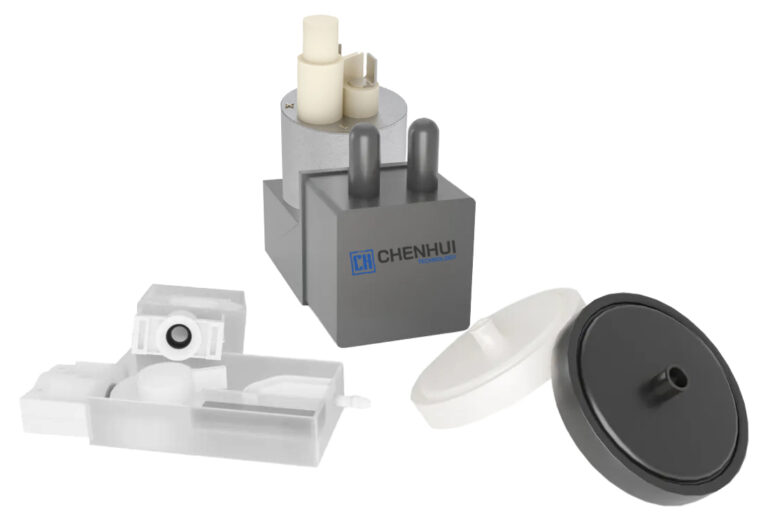

Ink sac (it is recommended to check once every 1~2 months)

Observe whether the filter is black and blocked, and whether the material is hard and depressurized.

When the DTF printer with powder machine print line is disconnected, you can first replace the new ink sac to check the ink supply status.

Ink stack (it is recommended to replace the sealing rubber ring every 3 months)

Regularly check whether the ink absorption force is normal. Use a manual ink pump to test whether it can be drawn smoothly.

If the nozzle is not sealed tightly, it is recommended to replace the ink stack or the sealing gasket.

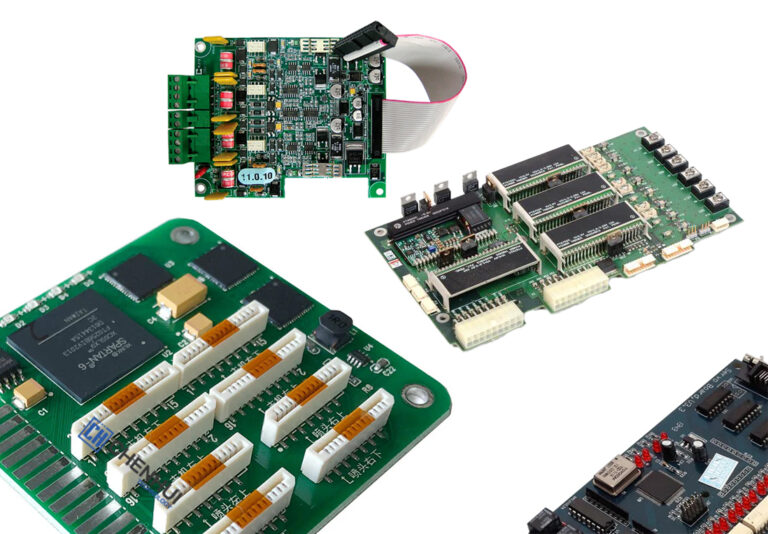

Data cable and motherboard connection end (check once a week)

Clean the dust on the socket end and check whether there are bent needles and poor contact.

If the nozzle pattern is misaligned, garbled, or ink is not produced locally, it may be a signal interruption and the data cable needs to be replaced.

Negative pressure ink supply system (check before starting the machine every day)

Observe whether there is air leakage and discontinuous ink supply. Whether the ink pump has weakened suction force and whether there is abnormal liquid level in the negative pressure tank. If the ink supply is found to be unstable, it is recommended to replace the pump tube and calibrate the negative pressure value.

Common maintenance suggestions

When the ink stack has weakened ink absorption force and the seal has deteriorated, it should be replaced as a whole. Avoid repeated plugging and unplugging of the data cable to cause the pins to loosen, and the stability of the connector should be checked regularly by a technician.

Through the above regular maintenance and parts inspection, the frequency of abnormal printing can be greatly reduced, the service life of the DTF printing printhead can be extended, and rework and loss can be reduced. If you need to obtain suggestions on parts selection, please feel free to consult.